Before you begin a hospital recycling program, it’s critical to understand what types of plastics are recyclable. HPRC walks you through with this simple visual guide, part of our comprehensive Hospicycle toolkit, helping you understand what kinds of plastics your program can include and what specific clinical materials they are found in.

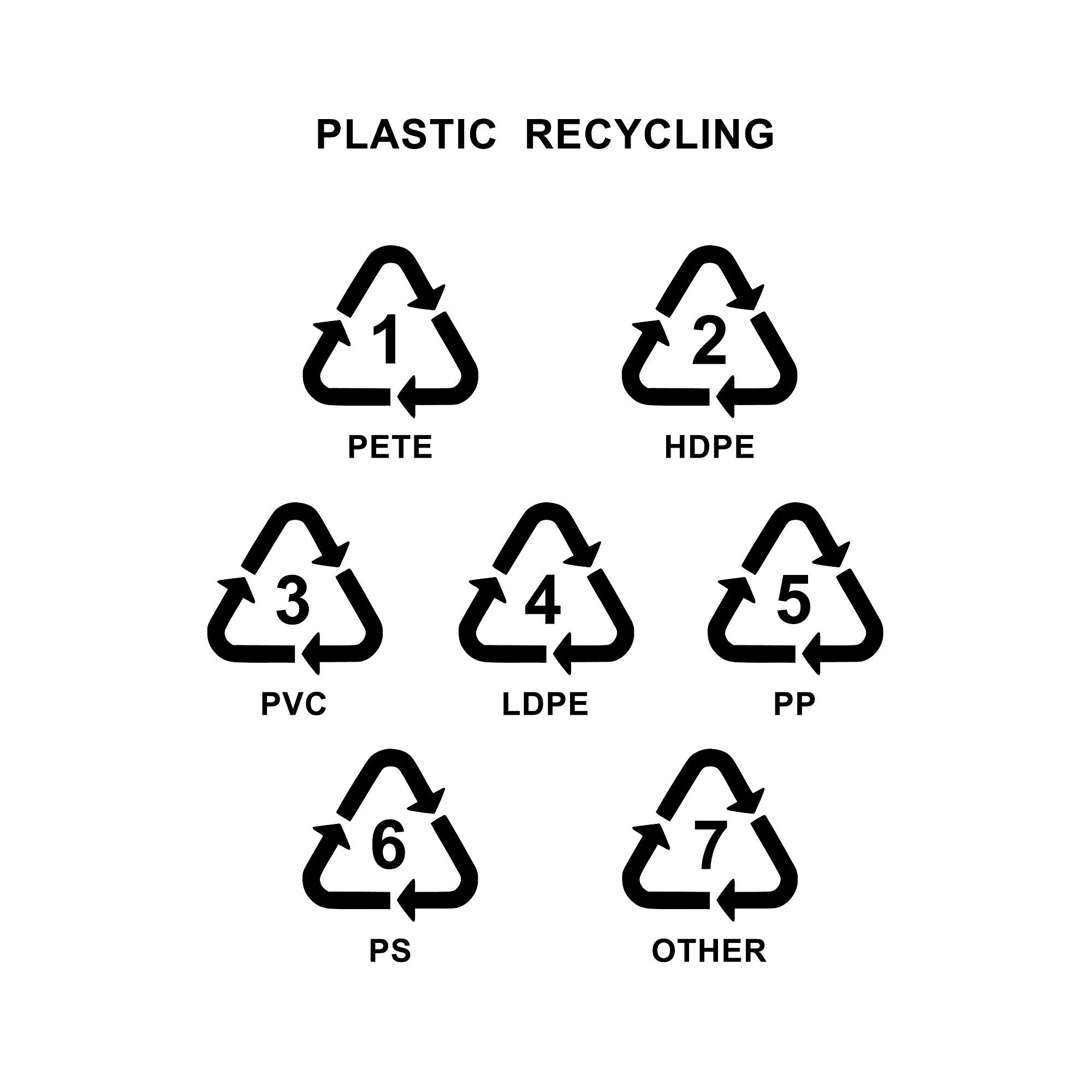

One important piece of information about a given plastic will be its Resin Identification Code (the number in the recycling triangle often found on the bottom of an item.) This numbering system was created by the PLASTICS Industry Association in order to help make recycling plastics easier. (Learn more here.) This number is what’s being referenced when you see a material referred to as “#5” or “#2” and gives important information to recyclers about the product’s chemical makeup.

Overview of the Most Common Healthcare Plastics

Sterilization Wrap

Commonly referred to as “blue wrap”, sterilization wrap is a sterile material that protects surgical instruments and other items from contamination. If collected before surgery, it is clean material that can be easily collected. It is often made from polypropylene (PP) and may then be recycled with other #5 materials or can be collected and baled separately to increase its value.

Some wrap materials can also include paper-based materials, check with the manufacturer if you are not sure of the material.

Irrigation Bottles

Irrigation bottles are commonly used in operating rooms. These bottles can be drained and collected for recycling. They are often made from polypropylene (PP), which can be recycled with other #5 materials. Some saline bottles are made from high density polyethylene (HDPE), which may be recycled with other #2 materials. Check with the manufacturer if you are not sure of the material.

Basins, Pitchers, Trays

Rigid colored and opaque plastic containers such as water pitchers and patient care basins and trays are typically made from polypropylene (PP) and may be recycled with #5 materials.

Flexible, Semi-rigid, or Rigid Primary Packaging

Flexible, semi-rigid, or rigid sterile barrier packaging is a common package design used to hold medical devices for sterilization and distribution. These packages are often constructed from two different types of materials and/or multi-material film laminations or co-extrusions. Tyvek® (high-density polyethylene) and films constructed from Polyester, Polyethylene, Polyamides, Polypropylene, and Ionomers are common materials used in these packages. These package designs are often referred to as pouches, header bags, vented bags, blister packs or film bags. Tyvek® lids, once removed from rigid trays may also be segregated into this stream. As noted, Tyvek® is HDPE but it may be difficult to visually differentiate Tyvek® from paper. Both have a similar appearance; however, long intertwined fibers can be seen in Tyvek® material when a light source is placed behind the material. Also, paper tears easily while Tyvek® is difficult to tear, although some coated or reinforced paper is also difficult to tear.

Flexible Clear Packaging

Flexible clear packaging includes shrink wrap, stretch film, and plastic bags and is usually found in large quantities at incoming dock areas and as secondary and tertiary packaging for healthcare products. Flexible clear packaging is made from polyethylene (PE) and may be recycled with #2 materials.